Change Language :

Industry 4.0 in crane technology

Tech up & cost down

Extend product service life efficiently with smart condition monitoring solutions

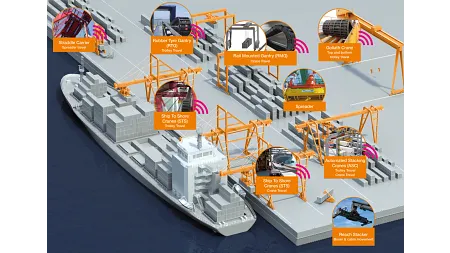

Different areas of application in the port ...

... always the right solution at hand with smart plastics from igus

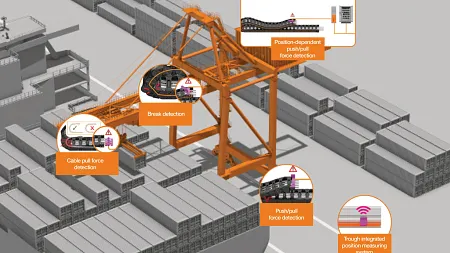

Reliable condition monitoring of cranes can be so simple ... with smart plastics i.Sense

How does predictive maintenance work at igus?

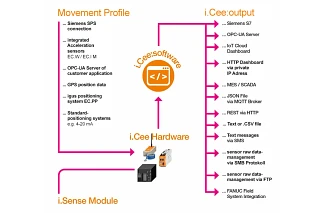

Only the smart networking of individual components creates the solid foundation for predictive maintenance concepts. At igus, we call our predictive maintenance system i.Cee.

The central element of this system is the i.Cee software. This software, combined with sensors on the energy chain, the plain bearing bushing or a linear carriage, transform stock products into smart products. This upgrade enables you to determine the maximum service life of your igus product and the i.Cee system specifies the perfect time for servicing. Algorithms adjust the service life and service time according to usage. With the software provided by us, a few sensors and the new i.Cee:plus II communication module, standard products available from stock can be turned into smart energy supply systems or bearing technology in no time at all.

You alone decide on the route & access of the data

Data transfer within your local company network (i.Cee:local) or via the secure cloud (i.Cee:cloud)

chains for cranes®

3D CAD portal for smart plastics

Designing intelligent energy chain systems faster. CAD models for all smart components.

Our intelligent e-chain systems are already being used reliably in many hundreds of thousands of applications worldwide - from beverage vending machines and CNC machines to steelworks. Unsupported lengths can be bridged with ease and long travels are conceivable for a wide range of industries.

Industry 4.0: successfully implemented in practice

Tested for real-life use in the industry's largest test laboratory

Complete overview of smart plastics

Insight into the complete product portfolio for Industry 4.0

Table of contents:

- Condition monitoring (i.Sense)

- Condition monitoring products

- Application examples of condition monitoring

- Predictive maintenance (i.Cee)

- Application examples for predictive maintenance

- How does the data flow with predictive maintenance?

FAQs

What are igus smart plastics? What does Industry 4.0 mean? In our blog, you will find answers to the most frequently asked questions from our customers:

Consulting

I look forward to answering your questions

Hennlich, Industrijska d.o.o.+385 1 3874334Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr