Change Language :

Energy chains for special environments

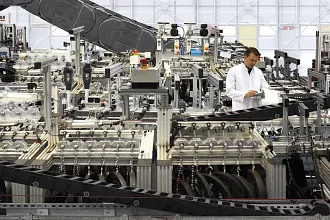

igus energy chains score highly even when used under the most demanding environmental conditions - whether cleanroom, very high dust exposure, hot swarf or aggressive chemicals - there is a solution for every challenge in the e-chains range. Together with customers, products and plastics have been developed, tested and successfully utilised for innovative applications. From completely sealed RX tubes, small-scale low-noise and low-vibration energy supply systems to elastic e-skins for cleanrooms or energy supply systems made of highly developed materials for different flammability classes - here you will find detailed information on solutions for special requirements.

Sector-specific energy chain

Energy supply types

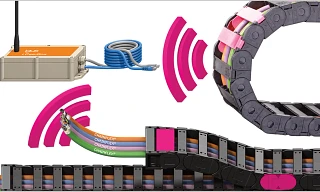

Service life monitoring for all e-chains

- New sensor technology enables measurement of percentage wear levels of the pin/bore connection

- Cost reduction through clear measurement of product service life - Avoidance of premature replacement of the e-chain system®

- Output of service life information and warning messages via HMI or local network systems

- Transmission of sensor and dynamic data via newly developed LoRa module

Easy to find, configure, calculate service life and order

Energy chains in use in special environments

Whether dirt, swarf, ESD, cleanroom, chemicals or extreme temperatures: igus offers a wide variety of solutions for special applications under special conditions.

Order an energy chain sample

Are you interested in our energy chain, but would like to hold it in your hands in order to get the best possible impression before making a final decision?

Then you are welcome to order a free sample from us.

More information

Tested!

Every year, 3,000 e-chain tests are carried out to withstand the toughest influences.

Energy chains catalogue

Download the e-chains catalogue directly online!

► Download here (PDF)

Consulting

I look forward to answering your questions

Hennlich, Industrijska d.o.o.+385 1 3874334Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr