Change Language :

Modular energy supply system for revolutionary multi-spindle lathe from DMG Mori

A fast-travelling rotating energy supply system allows a rotation angle of 540° in a tight installation space

After not even two years of development time, DMG MORI ushers in a new era of automatic turning machines with multiple spindles. The current MULTISPRINT series constitutes a technological revolution in automatic turning. Both the efficient lathe itself and the fast, precise and versatile production processes make the MULTISPRINT a machine with almost unlimited possibilities. Outstanding performance and quality, developed and manufactured in Italy, with support and professional back-up from Germany: We offer a special energy supply solution for both rotational and linear motion.

Products used

Up to twelve MULTISPRINT machines can be manufactured simultaneously in DMG MORI's new production hall in Brembate di Sopra.

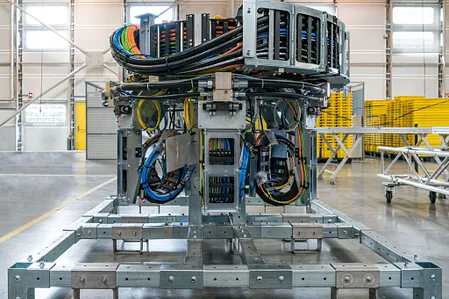

A look inside the MULTISPRINT shows the complex energy supply system from igus fully assembled on the machine's spindle drum.

To install the pre-fitted cables in the energy chains and the metal guides, the technicians in Cologne need approximately 2.5 days.

motion - magazine for energy chain systems

Tech up ... Cost down.

In this igus® magazine you will find numerous possibilities and application examples of how you can improve technology and / or reduce costs with ready-to-install energy chain systems.

Consulting

I look forward to answering your questions

Hennlich, Industrijska d.o.o.+385 1 3874334Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr