Change Language :

Saves three devices and a lot of space ... Now four sensors in one control cabinet module

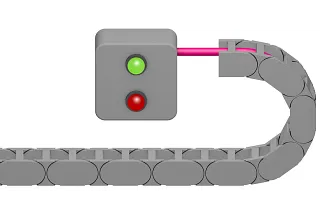

New, significantly improved second generation of the universal control cabinet module i.Sense:module II

The refined i.Sense:module II provides a wide range of new options and application scenarios for smart condition monitoring. Specifically, this new generation allows four status sensors to be connected simultaneously to just one control cabinet module, which means considerable space and cost savings. And not only in the control cabinet, but also in the chain itself as only one cable needs to be guided for every four sensors.

In addition to these obvious improvements, the new module now also offers a variety of typical Industry 4.0 use cases such as remote resetting via Wi-Fi or SMS, or the SMS/e-mail alarm function in the event of movement anomalies of the energy supply. The choice of communication channel for configuration and data download with the i.Sense:module II is particularly versatile. In addition to the stationary ports via USB or LAN cable, wireless connection via WLAN or Bluetooth with any conventional mobile device is also possible.

Part number: IS.EC.U04.01.01.0.BETA

Presentation of new products by Richard Habering

What does condition monitoring (i.Sense) do?

Condition monitoring is the fastest, simplest way to combine various igus products to form a self-monitoring smart plastics product. Sensors are attached to measure values (such as temperature, forces and sound waves/vibrations) within pre-defined limits. Values outside the limits result in an alert or a notification. Based on this information, a decision can be made about the next steps, maintenance or shutdown. If required, values outside defined limits can trigger a system shutdown to avoid expensive damage.

At igus, we use the term "i.Sense" to refer to condition monitoring.

How do the condition sensors (EC.P) work?

- The EC.P (EC = e-chain, P = pull force) sensor is assembled at the (floating) moving end of the e-chain.

- There, it measures the tensile forces acting on the e-chain.

- If they exceed a predetermined value, the sensor recognises this, reports it and, if necessary, switches off the system to prevent any expensive consequential or total damage.

Industry 4.0: realised in practice

Customer applications with smart plastics

Consulting

I look forward to answering your questions

Hennlich, Industrijska d.o.o.+385 1 3874334Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr